Metafoodx vs Others: Why Our AI Platform Redefines Food Operations

- Metafoodx

- Jan 9

- 3 min read

In commercial kitchens, visibility into production, consumption, and waste is no longer a “nice to have.” It is essential for improving margins, food safety, and sustainability.

Many solutions in the market help to track waste, but only be able to increase food-waste awareness effectively; Due to limited granularity of the data or requiring complex manual actions by the users, they fail to provide actionable insights and benefits to sustain deployment.

Metafoodx was built to do something more fundamental. We created an intelligent, real-time system that understands food in three dimensions, factors in temperature behavior, and turns operational data into decisions that teams can act on immediately. Our system is built with human-centric automation to be part of the future-proof infrastructure for commercial kitchens.

Here is what makes Metafoodx different in more detail.

Seeing Food in True Dimensions with 3D Vision

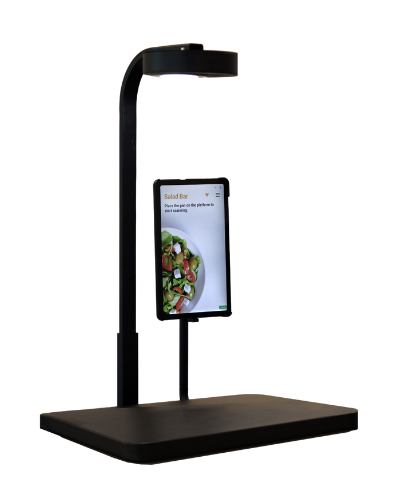

Metafoodx uses Intel RealSense 3D vision to capture real volumetric data instead of relying on flat 2D images. Our patented modeling calculates food volume and net weight, even when pans or containers look identical but differ in depth or density.

For example, a deep stainless pan may outweigh the food inside it. Our system removes that error through 3D segmentation and mass correlation. Density-aware classification also helps differentiate foods that appear similar in 2D, such as yogurt and sour cream or mashed potatoes and oatmeal. Most competing solutions use low-cost 2D webcams. Without volumetric understanding, their measurements and labels are less precise and often require manual correction.

A Modern, Scalable Platform Built for Real-Time Use

Metafoodx runs on consumer-grade tablets with GPU acceleration, Wi-Fi, Ethernet, and 5G support. AI runs directly on the device, so scans and classifications complete in under one second. Teams see the image, food label, and action prompts instantly.

Our secure AWS cloud architecture supports millions of scans and provides immediate dashboards and analytics. This combination of edge intelligence and cloud scalability allows faster decisions and faster feedback loops. Many competitor platforms process AI only in the cloud and analyze captured data with significant delay. This delays insight, prevents real-time alerts, and increases the burden on staff.

Temperature Intelligence that Improves Food Safety

Metafoodx integrates a built-in infrared sensor and AI thermal modeling to estimate true core temperature without probes or manual checks. The model accounts for 3D geometry, food type, ambient conditions, and heat-source effects. The system also forecasts temperature risk over time and alerts teams before a dish temperature falls into less safe ranges, such as below 135 °F for hot foods or above 41 °F for cold foods. This supports compliance and food safety while reducing manual thermometer checks. Other tools provide no temperature intelligence or predictive modeling, offering no relief for temperature-log keeping.

Touchless, Self-Learning AI

Our Vision Transformer AI reaches high accuracy from just seeing one or two images and improves automatically through continued use. Classification is touchless and nearly instant. LLM-assisted auto-labeling eliminates manual food tagging and speeds onboarding while supporting the ingredient and menu-item level food tracking

Metafoodx AI and its food item image library are backed by multiple patents and are based on millions of scans collected from real kitchen environments.

Competing products typically rely on third-party pre-trained models and do not support real-time food recognition on tracking devices.

End-to-End Visibility Across the Full Food Journey

Metafoodx tracks production prep, service-line activity, leftovers, and post-consumer plate waste. This creates a complete view from prep to plate and reveals the true source of loss, whether it is overproduction, menu mix, portioning, or consumer preference.

Most systems focus only on waste tracking which is too late and too little, or capture isolated points in the process which leaves significant gaps for operation insight. Metafoodx connects every stage with data insights.

Predictive AI for Smarter Production Planning

Metafoodx converts scan data into production forecasts and daily prep targets. The system learns from menu cycles, events, weather, and historical consumption to recommend what to cook and when to adjust volumes.

Teams can use Metafoodx as a full-cycle planning tool, even when their Kitchen Management System (KMS) does not offer forecasting capability.

Other platforms do not provide predictive production planning or menu-cycle optimization.

Built to Integrate Across the Enterprise

Metafoodx supports bi-directional integration with KMS platforms, POS, ERP, and analytics systems. Consumption, leftovers, and waste data can automatically inform purchasing, inventory, and production workflows. This gives operators a unified operational view instead of another disconnected data source.

Metafoodx system is built with menu-cycle logic and consumption-driven planning. It is also the system integrating with multiple KMS for bi-directional data sharing including menu plans and consumption records.

In Short

Metafoodx combines 3D vision, temperature intelligence, and predictive AI into one real-time operational platform. While other tools help teams review yesterday’s waste, Metafoodx helps prevent tomorrow’s.

The result is safer food, smarter kitchens, more accurate production, and measurable cost reduction across the entire operation.

Comments